Providing Effective Solutions Of Utilizing Water For Customers

Water Pump Accessories Manufacturers

-

Water Pump Controller

● Plastic part: new material no recycling, POLYAMIDE6 + GF30% ● Adjustable pressure button/differential pressure switch ... -

Water Pump Controller

1. This automatic water pump controller is used in water systems and can automatically start and stop water pumps based ... -

Water Pump Controller

1. This automatic water pump controller is used in water systems and can automatically start and stop water pumps based ... -

Water Pump Controller

● Special design body as bullet ● Adjustable Pressure Regulator is available ● Large connection thread: optional G2" siz... -

Mechanical Switch

Mechanical deformation makes the microswitch to act. When the pressure increases, the different sensing pressure compone... -

Water Pump Controller

1. This automatic water pump controller is used in water systems and can automatically start and stop water pumps based ... -

Water Pump Bearings

Bearing accessories can be customized and designed and manufactured to meet specific needs according to specific water p... -

Water Pump Impeller

The water pump impeller is an important part of the water pump and a key component to achieve the work of the water pump...

Start Our Cooperation!

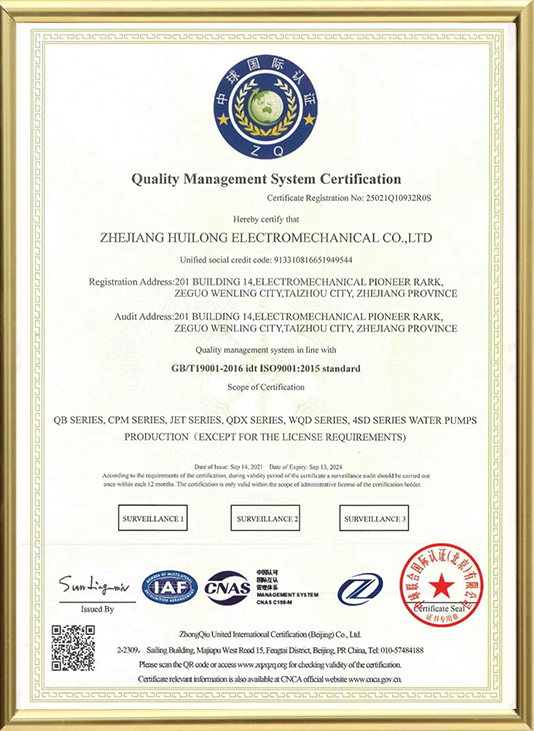

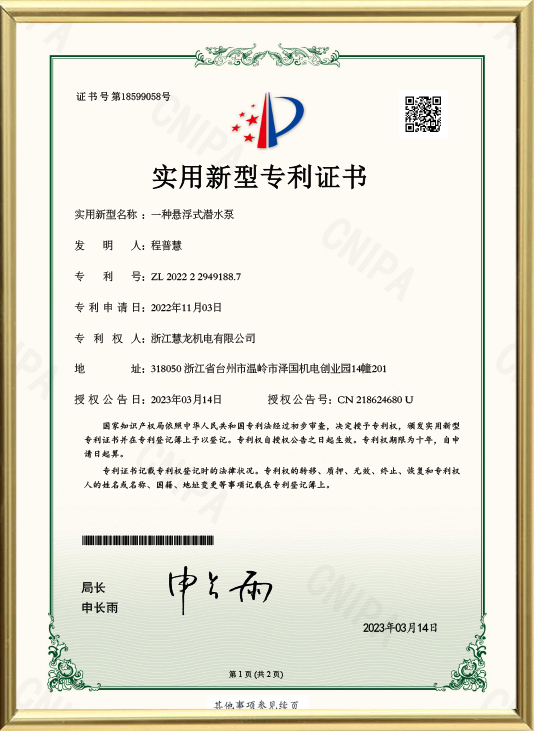

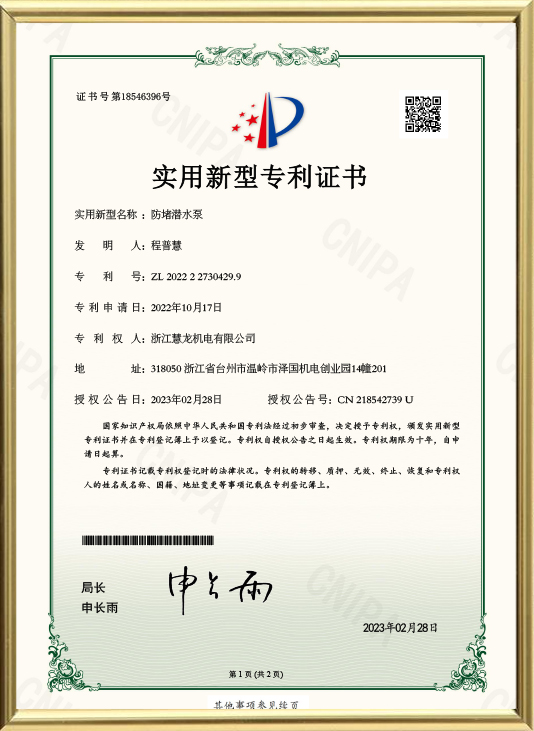

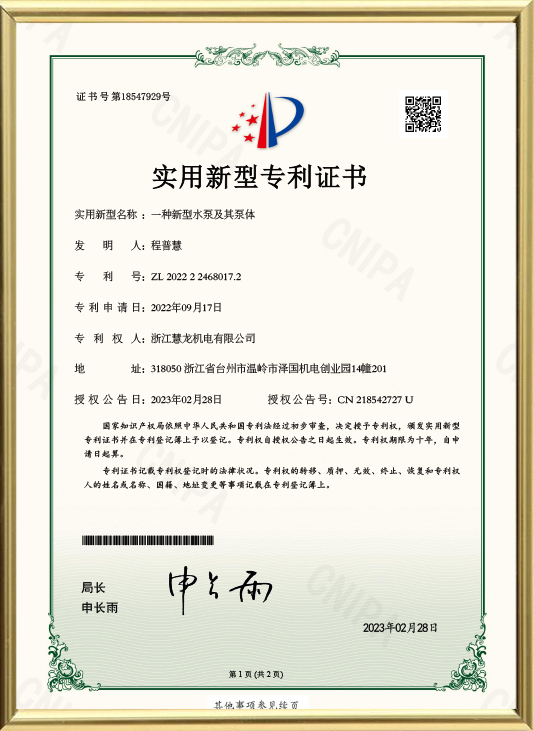

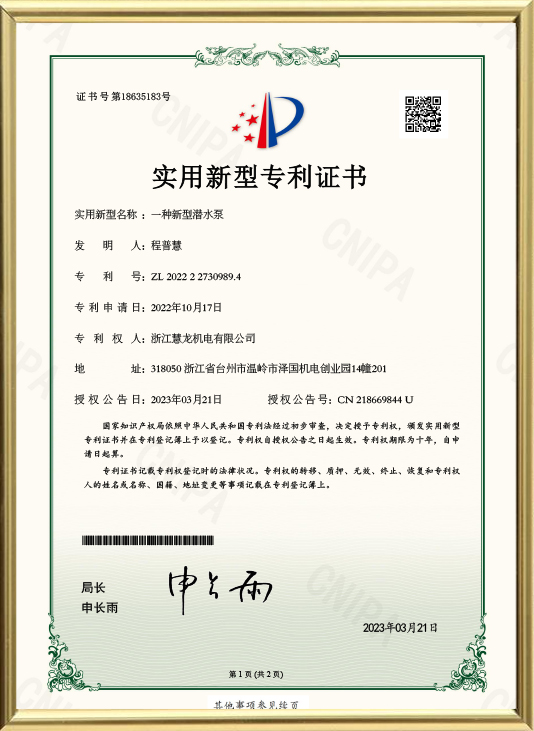

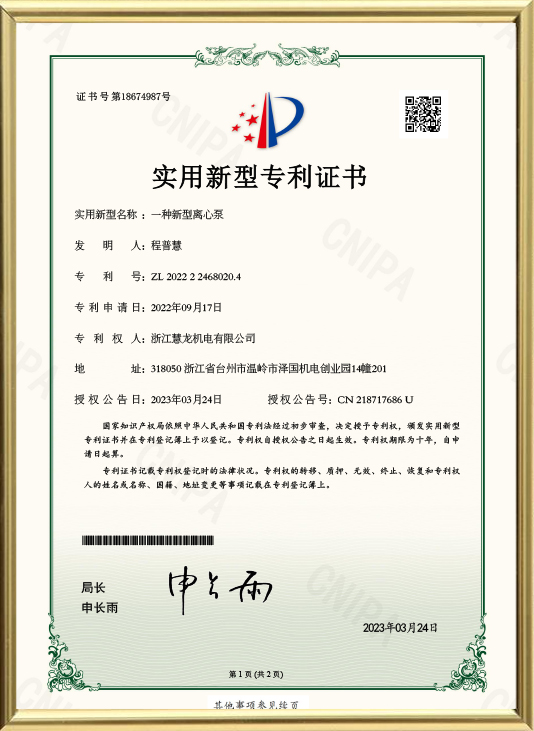

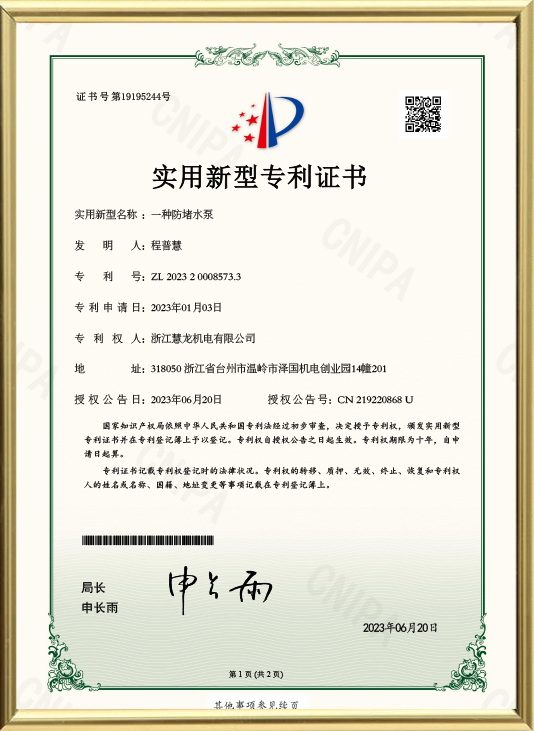

Zhejiang Huilong Electromechanical Co., Ltd. was established in 2007. The company covers an area of 6000m² and has more than 200 employees. It is an industry-trade enterprise specializing in the production of water pumps. It can produce more than 30,000 pumps of various types, mainly exported to Europe, Asia, Africa, America, and other regions.

The company has rich experience in the design and manufacture of submersible pumps and sewage pumps, advanced automated production lines, testing equipment, and production processes, a group of professional technical engineers, and a strong R&D team. Since the establishment of the company, the products have been produced in strict accordance with international standards. Every position in production, sales, and after-sales has a superb technical team to back it up. Every link is under strict quality control to ensure that all sales are high-quality products. The employees of the company always keep in mind that quality is the life of an enterprise, and they are professional because of concentration, and we have been working hard.

-

Products Integration

-

15+ Industrial Experience

-

Export To Over 35 Countries

-

7*24 Hours Customer Service

Recent News

Industry Knowledge

-

pending upgrade

-

pending upgrade

中文简体

中文简体 عربى

عربى