- Technical Parameters

- Ecterprise Strength

- Any Question

For water supply from wells or reservoirs

For domestic use for civil and industrial applications

Operating conditions

Maximum fluid temperature up to +35 ℃

Maximum sand content0.25%

Maximum immersion:80m

Minimum well diameter: Φ4"

Motor and pump

Rewindable motor or Full obturated screen motor

Three-phase:380V-415V/50Hz

Single-phase:220V-240V/50Hz

Equip with start control box or digital auto-control box

Pumps are designed by casing stressed

NEMA dimension standards

Curve tolerance according to ISO 9906

Options on request

Special mechanical seal

the voltage or frequency 60Hz

Single phase motor with built-in capacitor

| Components | Material |

| Pump extemal casing | AISI 304 SS |

| Delivery casing | Cast-Cu ASTM C855002AISI 304 SS |

| Suction lantern | Cast-Cu ASTM C855002 AISI 304 SS |

| Diffuser | Plastic:PC |

| lmpeller | Plastic:POM |

| Shaft | AISI316 ss AISI 304 SS |

| Shaft coupling | AISI 316 ss AISI 304 SS |

| Wear ring | AISI 304 ss & Ceramic |

| Motor external casing | AISI 304 SS |

| Top cover | Cast-Cu ASTM C85500 Cast-iron ASTM NO.30 |

| Bottom support | AISI 304 SS |

| Mechanical seal | Special seal for deep well (Graphite-Ceramic/TC) |

| Shaft | AISI 303 Ss-ASTM 1045/5410 |

| Bearing | NSK/C&U |

| Seal lubricant oil | Oil for food machinery and pharmaceutic use |

|

MODEL | P | DN | DIMENSIONS(mm) | WaIGHT(kg) | ||

| 1~220V/240V | 3~ 380V/415V |

kw | E | p | kg | ||

| 4SDM4/5 | 4SD4/5 | 0.37 | 11/4"/11/ 2"2" | 100 | 369 | 3.3 | |

| 4SDM4/7 | 4SD4/7 | 0.55 | 11/4"/11/ 2"2" | 100 | 426 | 3.8 | |

| 4SDM4/8 | 4SD4/8 | 0.75 | 11/4"/11/ 2"2" | 100 | 454 | 4.1 | |

| 4SDM4/9 | 4SD4/9 | 0.75 | 11/4"/11/ 2"2" | 100 | 482 | 4.4 | |

| 4SDM4/11 | 4SD4/11 | 1.1 | 11/4"/11/ 2"2" | 100 | 539 | 4.9 | |

| 4SDM4/13 | 4SD4/13 | 1.1 | 11/4"/11/ 2"2" | 100 | 595 | 5.4 | |

| 4SDM4/15 | 4SD4/15 | 1.5 | 11/4"/11/ 2"2" | 100 | 652 | 6 | |

| 4SDM4/17 | 4SD4/17 | 1.5 | 11/4"/11/ 2"2" | 100 | 708 | 6.5 | |

| 4SDM4/21 | 4SD4/21 | 2.2 | 11/4"/11/ 2"2" | 100 | 821 | 7.6 | |

| 4SDM4/24 | 4SD4/24 | 2.2 | 11/4"/11/ 2"2" | 100 | 938 | 8.4 | |

| 4SD4/28 | 3 | 11/4"/11/ 2"2" | 100 | 1051 | 9.5 | ||

| 4SD4/32 | 3 | 11/4"/11/ 2"2" | 100 | 1164 | 10.6 | ||

| 4SD4/36 | 4 | 11/4"/11/ 2"2" | 100 | 1277 | 11.7 | ||

| 4SD4/40 | 4 | 11/4"/11/ 2"2" | 100 | 1390 | 12.8 | ||

| 4SD4/45 | 5.5 | 11/4"/11/ 2"2" | 100 | 1531 | 14.1 | ||

| 4SD4/50 | 5.5 | 11/4"/11/ 2"2" | 100 | 1704 | 15.5 | ||

| 4SD4/55 | 7.5 | 11/4"/11/ 2"2" | 100 | 1845 | 16.8 | ||

| 4SD4/60 | 7.5 | 11/4"/11/ 2"2" | 100 | 1986 | 18.2 | ||

|

MODEL | P2 | DIMENSIONS(mm) | WEIGHT(kg) | |||||

| 1~220V/240V | 3~380V/415V | HP | M(S) | M(T) | B | C | M(s) | M(T) | |

| 0.37 | 0.37 | 0.5 | 313 | 313 | Φ95 | 38 | 6.9 | 6.6 | |

| 0.55 | 0.55 | 0.75 | 328 | 328 | Φ95 | 38 | 7.6 | 7.2 | |

| 0.75 | 0.75 | 1 | 343 | 343 | Φ95 | 38 | 8.2 | 7.9 | |

| 0.75 | 0.75 | 1 | 358 | 343 | Φ95 | 38 | 8.9 | 7.9 | |

| 1.1 | 1.1 | 1.5 | 378 | 378 | Φ95 | 38 | 9.8 | 9.5 | |

| 1.1 | 1.1 | 1.5 | 398 | 378 | Φ95 | 38 | 10.7 | 9.5 | |

| 1.5 | 1.5 | 2 | 423 | 413 | Φ95 | 38 | 11.8 | 11 | |

| 1.5 | 1.5 | 2 | 448 | 413 | Φ95 | 38 | 12.9 | 11 | |

| 2.2 | 2.2 | 3 | 501 | 448 | Φ95 | 38 | 15.3 | 12.6 | |

| 2.2 | 2.2 | 3 | 541 | 501 | Φ95 | 38 | 17.4 | 15.2 | |

| 3 | 4 | 526 | Φ95 | 38 | 16.4 | ||||

| 3 | 4 | 551 | Φ95 | 38 | 17.7 | ||||

| 4 | 5.5 | 581 | Φ95 | 38 | 19.2 | ||||

| 4 | 5.5 | 616 | Φ95 | 38 | 20.9 | ||||

| 5.5 | 7.5 | 672 | Φ95 | 38 | 22.9 | ||||

| 5.5 | 7.5 | 712 | Φ95 | 38 | 24.9 | ||||

| 7.5 | 10 | 762 | Φ95 | 38 | 27.4 | ||||

| 7.5 | 10 | 812 | Φ95 | 38 | 29.9 | ||||

| MODEL | P2 | DELVERY n≈2850 r/min | |||||||||||||

| 1~220V/240V | 3~380V/415V | kw | HP | Q(m3/h)/(l/min) | 0 | 0.6 | 1.2 | 1.8 | 2.4 | 3 | 3.6 | 4.2 | 4.8 | 5.4 | 6 |

| 0 | 10 | 20 | 30 | 40 | 50 | 80 | 70 | 80 | 90 | 100 | |||||

| 4SDM4/5 | 4SD4/5 | 0.37 | 0.5 | H(m) | 39 | 37 | 38 | 35 | 34 | 32 | 29 | 26 | 23 | 18 | 14 |

| 4SDM4/7 | 4SD47 | 0.55 | 0.75 | 54 | 52 | 51 | 49 | 48 | 45 | 41 | 37 | 32 | 28 | 19 | |

| 4SDM4/8 | 4SD4/8 | 0.75 | 1 | 62 | 59 | 58 | 56 | 54 | 51 | 47 | 42 | 36 | 29 | 22 | |

| 4SDM4/9 | 4SD4/9 | 0.75 | 1 | 70 | 67 | 65 | 63 | 61 | 57 | 53 | 48 | 41 | 33 | 25 | |

| 4SDM411 | 4SD4/11 | 1.1 | 1.5 | 85 | 82 | 80 | 77 | 75 | 70 | 65 | 58 | 50 | 40 | 30 | |

| 4SDM4/13 | 4SD4/13 | 1.1 | 1.5 | 101 | 97 | 94 | 91 | 88 | 83 | 76 | 69 | 59 | 48 | 36 | |

| 4SDM4/15 | 4SD4/15 | 1.5 | 2 | 116 | 111 | 108 | 105 | 102 | 96 | 88 | 79 | 68 | 55 | 41 | |

| 4SDM4/17 | 4SD4/17 | 1.5 | 2 | 131 | 128 | 123 | 120 | 116 | 109 | 100 | 90 | 77 | 62 | 46 | |

| 4SDM4/21 | 4SD4/21 | 2.2 | 3 | 162 | 156 | 152 | 148 | 143 | 134 | 124 | 111 | 95 | 77 | 57 | |

| 4SDM4/24 | 4SD4/24 | 2.2 | 3 | 188 | 178 | 174 | 169 | 163 | 153 | 141 | 127 | 109 | 88 | 66 | |

| 4SD4/28 | 3 | 4 | 217 | 208 | 203 | 197 | 19o | 179 | 165 | 148 | 127 | 103 | 77 | ||

| 4SD4/32 | 3 | 4 | 247 | 238 | 231 | 225 | 218 | 204 | 188 | 170 | 145 | 117 | 87 | ||

| 4SD4/36 | 4 | 5.5 | 278 | 268 | 260 | 253 | 245 | 230 | 212 | 191 | 163 | 132 | 98 | ||

| 4SD4/40 | 4 | 5.5 | 309 | 297 | 289 | 281 | 272 | 255 | 235 | 212 | 181 | 147 | 109 | ||

| 4SD4/45 | 5.5 | 7.5 | 348 | 335 | 326 | 317 | 306 | 287 | 285 | 239 | 204 | 165 | 123 | ||

| 4SD4/50 | 5.5 | 7.5 | 387 | 372 | 382 | 352 | 340 | 319 | 294 | 285 | 227 | 183 | 137 | ||

| 4SD4/55 | 7.5 | 10 | 425 | 409 | 398 | 387 | 374 | 351 | 324 | 291 | 249 | 202 | 150 | ||

| 4SD4/60 | 7.5 | 10 | 464 | 446 | 434 | 422 | 408 | 383 | 353 | 318 | 272 | 220 | 164 | ||

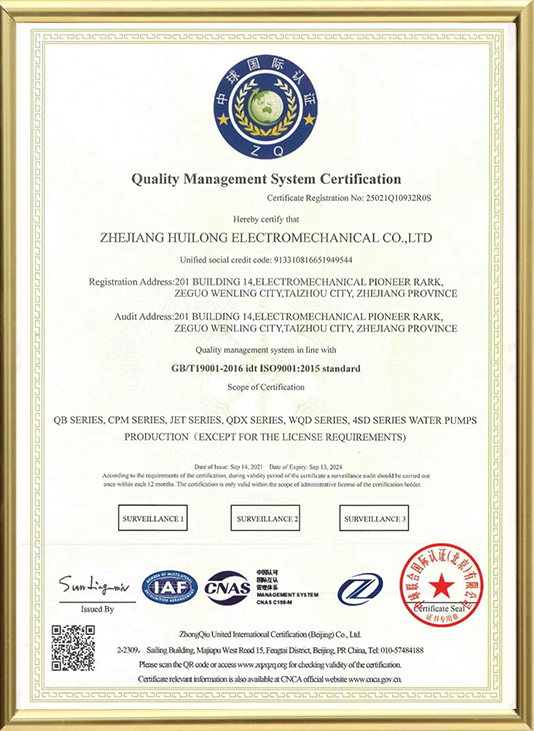

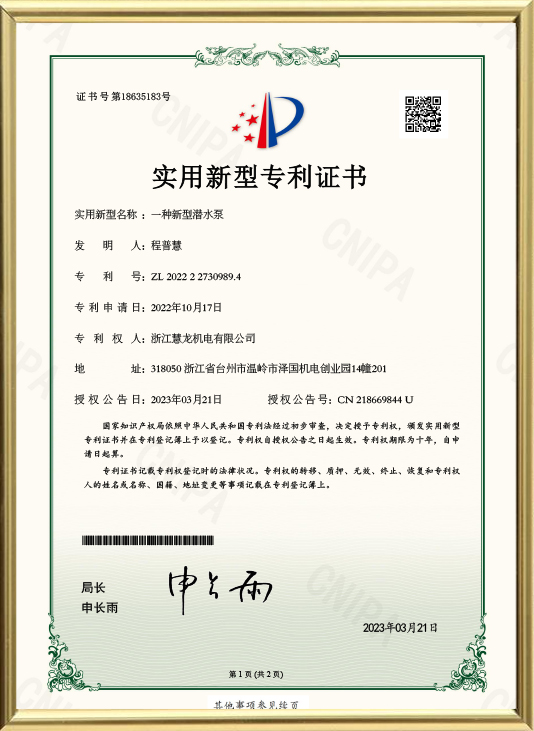

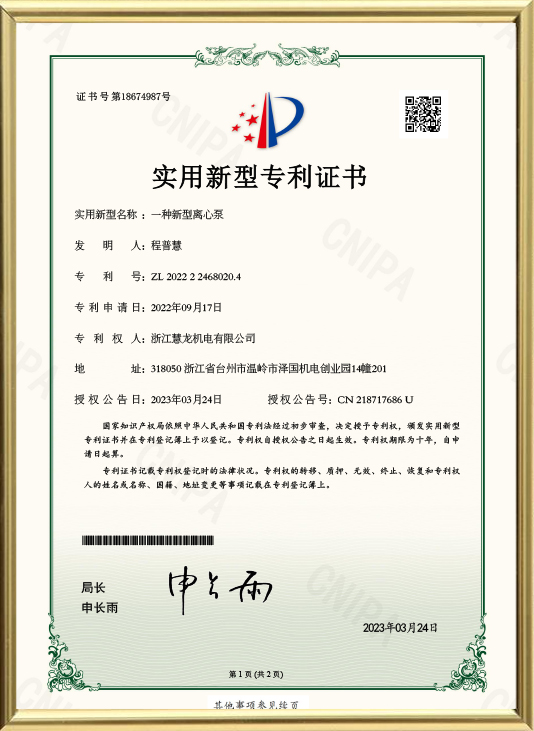

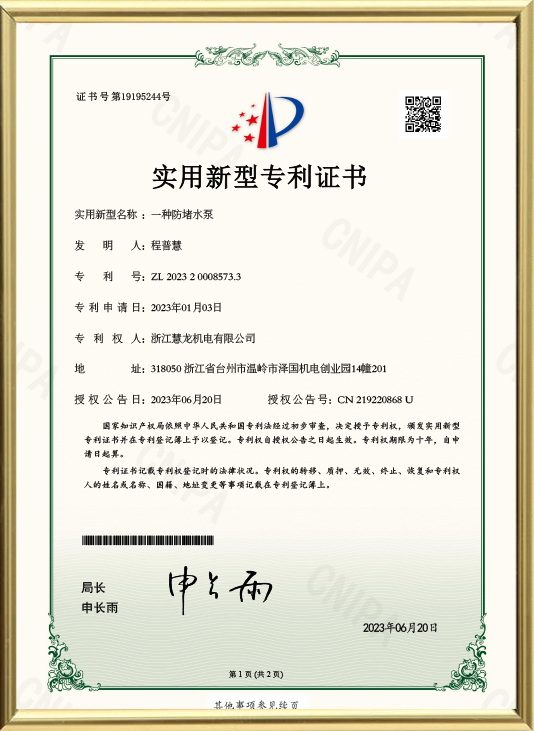

About Zhejiang Huilong Electromechanical Co., Ltd.

Zhejiang Huilong Electromechanical Co., Ltd. was established in 2007. The company covers an area of 6000m² and has more than 200 employees. It is an industry-trade enterprise specializing in the production of water pumps. It can produce more than 30,000 pumps of various types, mainly exported to Europe, Asia, Africa, America, and other regions.

The company has rich experience in the design and manufacture of submersible pumps and sewage pumps, advanced automated production lines, testing equipment, and production processes, a group of professional technical engineers, and a strong R&D team. Since the establishment of the company, the products have been produced in strict accordance with international standards. Every position in production, sales, and after-sales has a superb technical team to back it up. Every link is under strict quality control to ensure that all sales are high-quality products. The employees of the company always keep in mind that quality is the life of an enterprise, and they are professional because of concentration, and we have been working hard.

-

Products Integration

-

15+ Industrial Experience

-

Export To Over 35 Countries

-

7*24 Hours Customer Service

Popular Recommendations

-

PKM60 Series Centrifugal Pump

These pumps are suitable for handling clean water not containing abrasive particles and fluids which... -

PKM70 Series Centrifugal Pump

These pumps are suitable for handling clean water not containing abrasive particles and fluids which... -

QB Series Centrifugal Pump

These pumps are for clean water without abrasive particles and fluids which are not chemically ...

QB-1 Series Centrifugal Pump

These pumps are for clean water without abrasive particles and fluids which are not chemically ...

QB-2 Series Centrifugal Pump

These pumps are for clean water without abrasive particles and fluids which are not chemically ...

QB-3 Series Centrifugal Pump

These pumps are for clean water without abrasive particles and fluids which are not chemically ...

QB-4 Series Centrifugal Pump

These pumps are for clean water without abrasive particles and fluids which are not chemically ...

QB-5 Series Centrifugal Pump

These pumps are for clean water without abrasive particles and fluids which are not chemically ...

QB-6 Series Centrifugal Pump

These pumps are for clean water without abrasive particles and fluids which are not chemically ...

QB-7 Series Centrifugal Pump

These pumps are for clean water without abrasive particles and fluids which are not chemically ...

QB-8 Series Centrifugal Pump

These pumps are for clean water without abrasive particles and fluids which are not chemically ...

PS130 Series Centrifugal Pump

PS series self-priming water pumps are suitable forpumping clean water, thinks to the specific shape...Recent News

Industry Knowledge

-

pending upgrade

-

pending upgrade

中文简体

中文简体 عربى

عربى